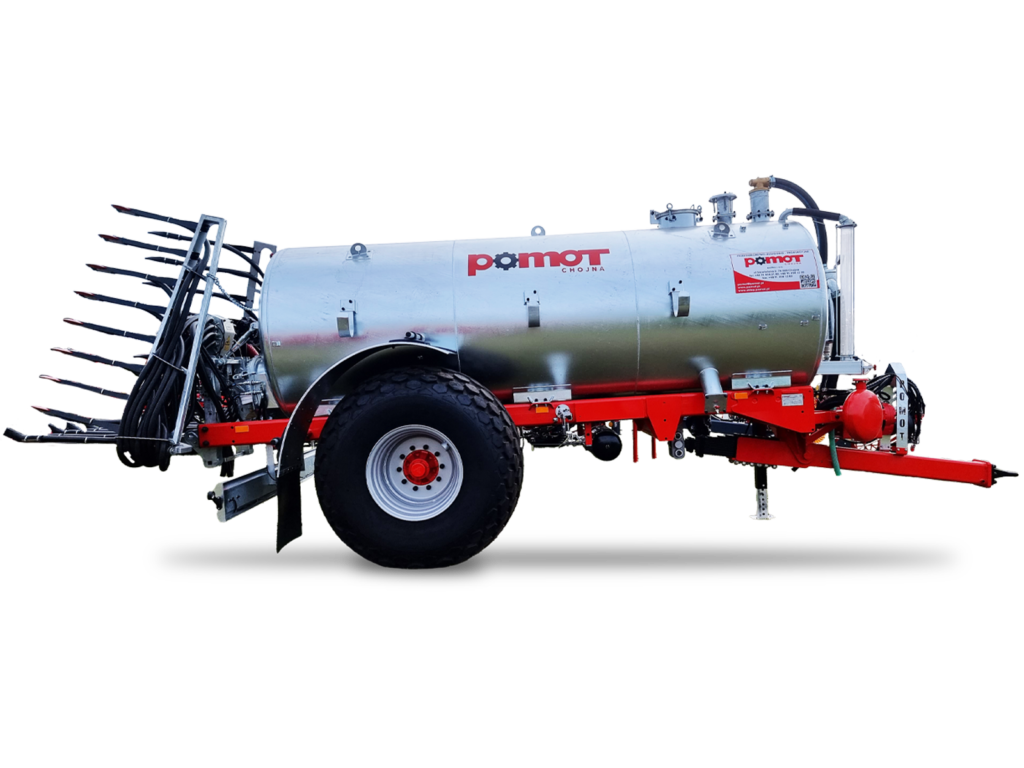

Standard Equipment

-

Tank

-

Hot-dip galvanized tank, inside and outside

-

Tank passivation to protect fresh galvanization from slurry action

-

Rear manhole Ø700 mm – manhole cover on a hinge

-

Tubular level indicator with sight glass

-

Drain nozzle with 1½″ valve at the lowest point of the tank

-

4″ sight glass on the rear tank end

-

Top manhole Ø350 mm

-

4″ safety valve

Chassis design: self-supporting or frame construction

-

Self-supporting: drawbar mounted on reinforced supports under the tank, hot-dip galvanized

-

Frame: tank mounted on a frame made of closed steel profiles

-

Replaceable drawbar eye – bolted, Ø50 mm

-

Mechanically adjustable support leg

-

Single-axle, single-axle with leaf spring suspension, or tandem axle with leaf spring suspension

-

Tires according to the table

-

Fenders

-

Two-line pneumatic braking system with 4-stage braking force adjustment

-

Mechanical parking brake

Compressor – type according to table

-

Drive: 540 rpm or, on request, 1000 rpm

-

Reinforced temperature-resistant hoses connecting fittings

-

Overflow protection with dual ball valve and sight glass on top of the tank, plus siphon with sight glass

-

Vacuum-pressure gauge

-

Two safety valves: overpressure valve up to 0.05 MPa and vacuum valve up to -0.05 MPa

-

Oil separator – wet air filter and silencer for compressor noise reduction

Suction ports

-

6″ suction ports Ø150 mm

-

Main discharge port in the rear manhole cover: 6″ with hydraulic 6″ gate valve

-

Front left and right: capped, prepared for installation of manual valves

-

Rear port: capped, prepared for installation of manual valve

Electrical system

-

12V electrical and lighting installation

Suction hose system

-

6″ (Ø150) suction hose

-

Transport brackets for suction hose

-

Suction hose with strainer basket to prevent large objects from entering

-

Suction hose length: 6 meters

Spreading equipment

-

Shaped splash plate, POMOT 94 design, spreading width up to 14 m

Type approval certificate

-

Enabling registration and legal operation on public roads

PTO shaft included

Specifications by version:

VERSION SUSPENSION TIRE DIMENSIONS TIRE SIZE COMPRESSOR TYPE SELF-SUPPORTING DESIGN ECONOMIC single-axle 1235×550 550/60×22.5 MEC or KD 8000 STANDARD single-axle 1340×600 600/55×26.5 MEC or KD 8000 CLASIC single-axle 1580×587 23.1×26 HD MEC 9000 or KD 10000 PREMIUM single-axle 1590×714 28Lx26 MEC 9000 or KD 10000 FRAME DESIGN ECONOMIC single-axle 1235×550 550/60×22.5 MEC or KD 8000 STANDARD single-axle 1340×600 600/55×26.5 MEC or KD 8000 CLASIC single-axle 1580×587 23.1×26 HD MEC 9000 or KD 10000 PREMIUM single-axle 1590×714 28Lx26 MEC 9000 or KD 10000 FRAME DESIGN – SPRUNG SINGLE-AXLE ECONOMIC single-axle sprung 1235×550 550/60×22.5 MEC or KD 8000 STANDARD single-axle sprung 1340×600 600/55×26.5 MEC or KD 8000 CLASIC single-axle sprung 1580×587 23.1×26 HD MEC 9000 or KD 10000 PREMIUM single-axle sprung 1590×714 28Lx26 MEC 9000 or KD 10000 -